To circulate the coolant around the engine in a circular motion, a Water Pump is required. Heat from engine combustion is absorbed by coolant, which then passes through the radiator to release the heat before being recycled back into the engine. As long as the engine is running, this process is repeated.

It is situated between the radiator and the engine and is driven by a pulley through a timing or fan belt.

The Water Pumps consist of the following components

Each of the materials is chosen according to its performance level, quality, customer demands, and operating conditions.

Through the Water Pump bearing, the crankshaft’s revolution power is transferred to the impeller. The coolant escapes through impeller vanes.

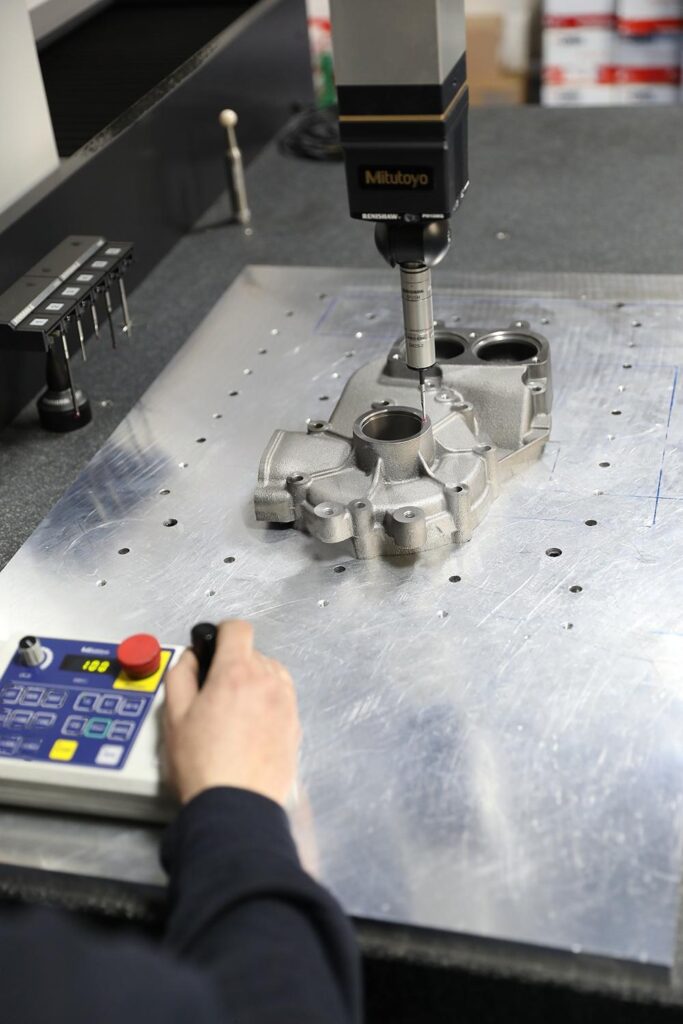

The above-listed components are all manufactured using conventional materials and extremely precise machinery. All of the Water Pumps are assembled with the help of necessary fixtures and tools, and they are all tested for leaks according to engine

characteristics like R.P.M., water, temperature, pressure, and so on.

Certificate Registration No. – 99 100 22155

© 2024 Conic Components Pvt. Ltd. All rights reserved.